A global provider of track maintenance machinery who have a manufacturing base in Sydney, recently reached out to SafeSmart Access to provide a solution for safe access when installing HVAC systems and roof sections on the machinery they manufacture.

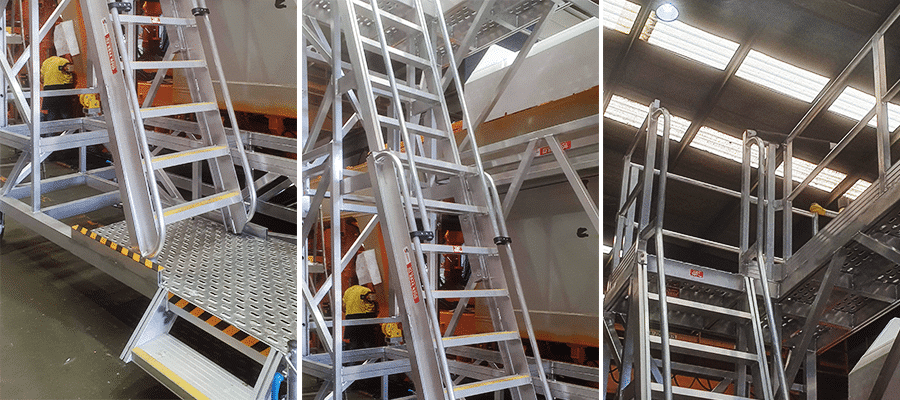

SafeSmart assessed the problem onsite and identified that a custom platform would be required in order to suit the varying machines and applications with adjustable height and telescopic guardrails. The telescopic guardrails connect across the roof of the rail maintenance machinery to create an edge protected work surface on the roof. The high-tensile aluminium and in-house design and engineering gives the custom platform a 500kg safe working load. The platform was supplied with large pneumatic castors for easy manoeuvring across rail tracks and crane lifting points were also added to allow for alternative methods of relocation.

SafeSmart’s Dean Strange says that the client is immediately seeing benefits from the Adjustable Roof Access platforms.

As a result of the full surround edge protection the custom platform provides, efficiency and productivity have increased as they no longer require static lines and harnesses to access the roof.

“The operator can’t afford to have the risk of worker injury or downtime associated with height access, so these platforms will address this risk and help them to deliver on their turnaround times.”

SafeSmart now has the product added to their custom category on their Australian website, with more specific details, as a reference for global train operators who may have similar applications.

The Adjustable Roof Access Platforms are compliant to AS1657:2018.